In this ever challenging business environment as we thrive to tailor make our offerings to your exact requirements, we have taken a step further to provide you with the TML Fully Built Solutions.

Today's fiercely competitive business scenario means that you need to be ready on Day one with your asset and need to focus on your business fully. That is where we step in to take away all your worries.

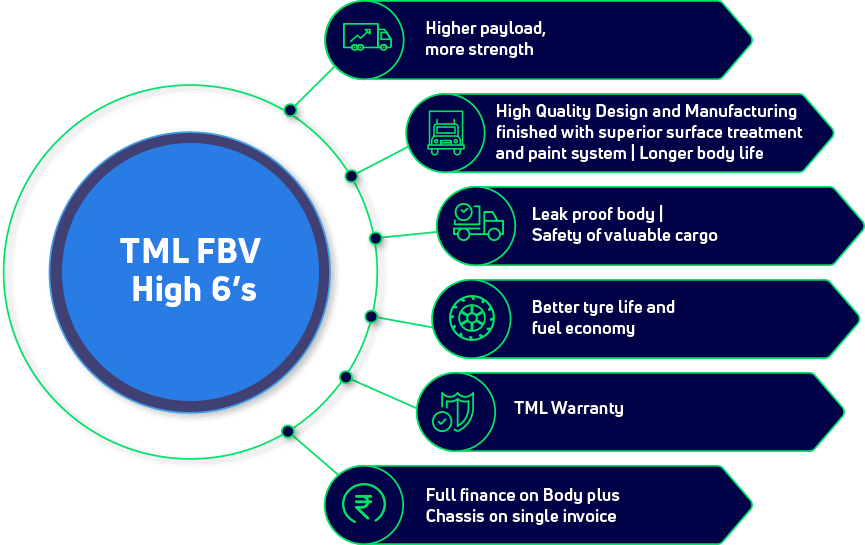

The Fully Built Solutions' range from Tata Motors promises the High 6s that ensure you earn the maximum commercial gains and have complete peace of mind when it comes to your application requirements including the operation and maintenance of the bodies.

Now choose from the wide range of solutions on our truck and tractor platforms and enjoy the convenience of Ready-to-run vehicles, single invoice funding, hassle free registration, durable and reliable bodies designed, manufactured and maintained with the best in class processes, materials and techniques ensuring you earn more per trip.

Excellence and Trust are what we serve with our Fully Built Solutions range now with the Tata Motors High 6s

Take your business to newer heights with our world class chassis with optimally designed bodies that offer higher and faster return on investment giving you complete peace of mind.

RIGID TRUCKS

REFRIGERATED CONTAINER ON ULTRA 1918.T BS6

| MODEL | 24 ft MS Reefer Container on ULTRA 1918.T_56WB | 24 ft PPGI Reefer Container on ULTRA 1918.T_56WB | 32 ft MS Reefer Container on ULTRA 1918.T_68WB |

| Body Dimensions (LxWxH) | 7320 mm x 2440 mm x 2590 mm | 7500 mm x 2500 mm x 2700 mm | 9805 mm x 2600 mm x 2805 mm |

| Internal Body Dimensions (LxWxH) | 6970 mm x 2190 mm x 2240 mm | 7240 mm x 2300 mm x 2470 mm | 9455 mm x 2340 mm x 2465 mm |

| Floor | 125 mm Sandwich panel construction with GRP Sheet + PU Foams + Aluminum T Grating | 120 mm Sandwich panel construction with GRP Sheet + XPS Foams + Aluminium T Grating | 125 mm Sandwich panel construction with GRP Sheet + PU Foams + Aluminum T Grating |

| Side panel | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 0.7mm PPGI sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) |

| Door | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.5mm GRP sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) |

| Headboard/Front panel | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.5mm GRP sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) |

| Roof | 125mm PU Foam | 120mm PU Foam | 125mm PU Foam |

| Ambient Temperature | 50 ⁰C | ||

| Operating Temperature range | (-20⁰C+25⁰C) | ||

| Insulation Density | 38-40 kg/m | ||

| Refrigeration Unit: Make & Model | (Carrier) Supra 1150 / (Thermoking) T800 | (Carrier) Supra 1150 / (Thermoking) T1000 | |

| Internal Lights | 3 nos. - 6 " LED light sunken type, 24 V, equi-spaced, flush with roof | ||

| Electricals | As per regulations | ||

| Standard Accessories | Mudguard flap / side indicators / internal lights / others | ||

| Painting & Rust Prevention | Polyurethane (PU) finish paint | ||

| Additional Fitments | Strip curtain with SS brackets | ||

| Application | Fruits & Vegetables, Dairy, Pharmaceuticals, Meat, Frozen food, Sea food, Beverages and Flowers | ||

| Optional Fitments | Rear parking camera and camera inside container; Door opening sensor; Small U hook; Temporary partition; Load sensor with GPS tracking; Anti fuel theft system - OTP enabled padlock | ||

MS CONTAINER ON ULTRA 1918.T BS6

| MODEL | 24 ft MS Container on ULTRA 1918.T_56WB | 32 ft MS Container on ULTRA 1918.T_68WB |

| Body Dimensions External (LxWxH) | 7 315 mm x 2 440 mm x 2 725 mm | 9780 mm x 2590 mm x 3255 mm |

| Body Dimensions Internal (LxWxH) | 7193 mm x 2370 mm x 2440 mm | 9600 mm x 2525 mm x 2955 mm |

| Side Panel / Door / Front Panel | 1.6 mm Corrugated MS Sheet | |

| Floor Sheet | 3.15 mm Mild Steel (chequered) | |

| Wind Deflector | Tubular Structure of GI/FRP Sheet | |

| Side Markers | 3 nos. on each side (total 6) | 5 nos. on each side (total 10) |

| LED Roof Lights | 2nos. | 2nos. |

| Electricals & Reflective Tapes | As per regulation | |

| Application | Consumer Durables, FMCG, Parcel, E-Commerce, Industrial goods, Auto Components, Agri Bags | |

| Optional Fitments | Rear parking camera and camera inside container; Door opening sensor; Small U hook; Temporary partition; Load sensor with GPS Tracking; Anti fuel theft system; OTP enabled padlock | |

HIGH SIDE DECK LOAD BODY ON ULTRA 1918.T BS6

| MODEL | 20ft High Side Deck Steel Floor on ULTRA 1918.T_49WB | 20ft High Side Deck Wooden Floor on ULTRA 1918.T_49WB | 24ft High Side Deck Steel Floor on ULTRA 1918.T_56WB | 24ft High Side Deck Wooden Floor on ULTRA 1918.T_56WB |

| Body Dimensions (LXWXH) | 6286 mm x 2424 mm x 2158 mm | 6286 mm x 2424 mm x 2158 mm | 7550 mm x 2424 mm x 2135 mm | 7550 mm x 2424 mm x 2135 mm |

| Floor | 1.4 mm Corrugated High Strength Steel | 25 mm Composite wood | 1.6 mm Mild Steel Corrugated Sheet | 25 mm Composite wood |

| Side panel | 1.1 mm Corrugated High Strength Steel | 1.6 mm Mild Steel Corrugated Sheet | ||

| Door | 1.2 mm Corrugated High Strength Steel | 1.6 mm Mild Steel Corrugated Sheet | ||

| Headboard/ Front panel | 1.2 mm Corrugated High Strength Steel | 1.6 mm Mild Steel Corrugated Sheet | ||

| Painting | Polyurethane finish paint | Polyurethane finish paint | ||

| Application | FMCD, Industrial goods, Agri Bags, Steel parts, FMCG, Parcel, Pipes & tubes, Auto Components, Barrels, Cement Bags, Coal etc | |||

DROP SIDE DECK LOAD BODY ON ULTRA 1918.T BS6

| MODEL | 24ft 11 inch DSD_Chequered Floor on ULTRA 1918 _68WB_5L_Turbotron |

| Body Dimensions (LXWXH) | 7594 mm x 2489 mm x 914 mm |

| Floor | 3 mm Mild Steel Chequered Sheet |

| Side panel | 2 mm Mild Steel Corrugated Sheet |

| Door | 2 mm Mild Steel Corrugated Sheet |

| Headboard/ Front panel | 2 mm Mild Steel Corrugated Sheet |

| Painting | Polyurethane finish paint |

| Application | FMCD, Industrial goods, Agri Bags, Steel parts, FMCG, Parcel, Pipes & tubes, Auto Components, Barrels, Cement Bags, Coal, Palletized Loads like of Beverages etc. |

WATER TANKER ON ULTRA 1918.T BS6

| MODEL | 12KL Water Tanker on ULTRA 1918 Ex_45WB |

| Body Dimension | 4800 mm x 2235 mm x 1420 mm |

| Outer Shell Thickness | 3 mm Mild Steel |

| Dish End Thickness | 3 mm Mild Steel |

| Compartment | 3 Compartments |

| Manhole | 3 Manholes |

| Application | Bulk Water transportation |

REFRIGERATED CONTAINER ON LPT 1918 5L Turbotronn Cowl BS6 / LPT 1918 Cowl BS6

| MODEL | 32 ft MS Reefer Container on LPT 1918 _68WB_5L_Turbotron | 32 ft PPGI Reefer Container on LPT 1918 _68WB_5L_Turbotron |

| Body Dimensions (LxWxH) | 9760 mm x 2590 mm x 2800 mm | 9715 mm x 2540 mm x 2718 mm |

| Internal Body Dimensions (LxWxH) | 9450 mm x 2340 mm x 2460 mm | 9455 mm x 2340 mm x 2465 mm |

| Floor | 125 mm Sandwich panel construction with GRP Sheet + PU Foams + Aluminum T Grating | 120 mm Sandwich panel construction with GRP Sheet + XPS Foams + Aluminium T Grating |

| Side panel | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 0.7mm PPGI sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) |

| Door | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.5mm GRP sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) |

| Headboard/Front panel | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.5mm GRP sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) |

| Roof | 125mm PU Foam | 120mm PU Foam |

| Ambient Temperature | 50 ⁰C | |

| Operating Temperature range | (-20⁰C+25⁰C) | |

| Insulation Density | 38-40 kg/m | |

| Refrigeration Unit: Make & Model | (Carrier) Supra 1150 / (Thermoking) T1000 | |

| Internal Lights | 3 nos. - 6 " LED light sunken type, 24 V, equi-spaced, flush with roof | |

| Electricals | As per regulations | |

| Standard Accessories | Mudguard flap / side indicators / internal lights / others | |

| Painting & Rust Prevention | Polyurethane (PU) finish paint | |

| Additional Fitments | Strip curtain with SS brackets | |

| Application | Fruits & Vegetables, Dairy, Pharmaceuticals, Meat, Frozen food, Sea food, Beverages, Flowers | |

| Optional Fitments | Rear parking camera and camera inside container; Door opening sensor; Small U hook; Temporary partition; Load sensor with GPS tracking; Anti fuel theft system - OTP enabled padlock | |

MS CONTAINER ON LPT 1918 5L Turbotronn Cowl BS6 / LPT 1918 Cowl BS6

| MODEL | 32 ft_8.9 ft MS Container on LPT 1918 _68WB_5L_Turbotron | 32 ft_9.5 ft MS Container on LPT 1918 _68WB_5L_Turbotron |

| Body Dimensions (LxWxH) | 9884 mm x 2590 mm x 2680 mm | 9850 mm x 2590 x 3180 mm |

| Body Dimensions Internal (LxWxH) | 9754 mm x 2525 mm x 2425 mm | 9754 mm x 2525 mm x 2955 mm |

| Side Panel / Door / Front Panel | 1.6 mm Corrugated Mild Steel | |

| Floor Sheet | 3.15 mm Mild Steel (chequered) | |

| Wind Deflector | Tubular Structure of GI/FRP Sheet | |

| Side Markers | 5 nos. on each side (total 10) | |

| LED Roof Lights | 2nos. | |

| Electricals & Reflective Tapes | As per regulation | |

| Application | Consumer Durables, FMCG, Parcel, E-Commerce, Industrial goods, Auto Components, Agri Bags | |

| Optional Fitments | Rear parking camera and camera inside container; Door opening sensor; Small U hook; Temporary partition; Load sensor with GPS Tracking; Anti fuel theft system; OTP enabled padlock | |

HIGH SIDE DECK LOAD BODY ON LPT 1918 5L Turbotronn Cowl BS6 / LPT 1918 Cowl BS6

| MODEL | 20ft High Side Deck_Steel Floor on LPT 1918 _48WB |

| Body Dimensions (LXWXH) | 6 150 mm x 2 358 mm x 2 154 mm |

| Floor | 1.6 mm Mild Steel Corrugated Sheet |

| Side panel | 1.6 mm Mild Steel Corrugated Sheet |

| Door | 1.6 mm Mild Steel Corrugated Sheet |

| Headboard/ Front panel | 1.6 mm Mild Steel Corrugated Sheet |

| Painting | Polyurethane finish paint |

| Application | FMCD, Industrial goods, Agri Bags, Steel parts, FMCG, Parcel, Pipes & tubes, Auto Components, Barrels, Cement Bags, Coal etc |

* Above FBV variants are also available on LPT 1918 Cowl BSVI (Cummins Engine)

REFRIGERATED CONTAINER ON LPT 2818/2821_COWL BS6

| MODEL | 24 ft MS Reefer Container on LPT 2818/2821 _68WB_Cowl | 32 ft MS Reefer Container on LPT 2818/2821 _68WB_Cowl | 32 ft PPGI Reefer Container on LPT 2818/2821_68WB_Cowl |

| Body Dimensions (LxWxH) | 7320 mm x 2590 mm x 2590 mm | 9760 mm x 2590 mm x 2800 mm | 9750 mm x 2590 mm x 2831 mm |

| Internal Body Dimensions (LxWxH) | 6970 mm x 2340 mm x 2240 mm | 9450 mm x 2340 mm x 2460 mm | 9557 mm x 2396 mm x 2600 mm |

| Floor | 125 mm Sandwich panel construction with GRP Sheet + PU Foams + Aluminum T Grating | 125 mm Sandwich panel construction with GRP Sheet + PU Foams + Aluminum T Grating | 128 mm Sandwich panel construction with GRP Sheet + PUF Insulation + Aluminium T Grating |

| Side panel | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.4mm PPGI sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) |

| Door | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.5mm GRP sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) |

| Headboard/Front panel | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) | 1.5mm GRP sheet+ 100mm PU foams + 1.5mm GRP Sheet (Food grade) |

| Roof | 125mm PU Foam | 125mm PU Foam | 120mm PU Foam |

| Ambient Temperature | 50 ⁰C | ||

| Operating Temperature range | (-20⁰C+25⁰C) | ||

| Insulation Density | 38-40 kg/m | ||

| Refrigeration Unit: Make & Model | (Carrier) Supra 1150 / (Thermoking) T800 | (Carrier) Supra 1150 / (Thermoking) T1000 | |

| Internal Lights | 3 nos. - 6 " LED light sunken type, 24 V, equi-spaced, flush with roof | ||

| Electricals | As per regulations | ||

| Standard Accessories | Mudguard flap / side indicators / internal lights / others | ||

| Painting & Rust Prevention | Polyurethane (PU) finish paint | ||

| Additional Fitments | Strip curtain with SS brackets | ||

| Application | Fruits & Vegetables, Dairy, Pharmaceuticals, Meat, Frozen food, Sea food, Beverages, Flowers | ||

| Optional Fitments | Rear parking camera and camera inside container; Door opening sensor; Small U hook; Temporary partition; Load sensor with GPS tracking; Anti fuel theft system - OTP enabled padlock | ||

MS CONTAINER ON 2818/2821_COWL & ULTRA CAB BS6

| MODEL | 32 ft MS Container on SIGNA 2818/2821_68WB | 32 ft_8.9 ft MS Container on LPT 2818/2821_68WB | 32 ft_9.5 ft MS Container on LPT 2818/2821_68WB |

| Body Dimensions (LxWxH) | 9450 mm x 2590 mm x 2665 mm | 9884 mm x 2590 mm x 2665 mm | 9850 mm x 2590 mm x 2895 mm |

| Body Dimensions Internal (LxWxH) | 9245 mm x 2525 mm x 2440 mm | 9679 mm x 2525 mm x 2440 mm | 9645 mm x 2525 mm x 2670 mm |

| Side Panel / Door / Front Panel | 1.6 mm Corrugated Mild steel | ||

| Floor Sheet | 3.15 mm Mild Steel (chequered) | ||

| Wind Deflector | Tubular Structure of GI/FRP Sheet | ||

| Side Markers | 5 nos. on each side (total 10) | ||

| LED Roof Lights | 2nos. | ||

| Electricals & Reflective Tapes | As per regulation | ||

| Application | Consumer Durables, FMCG, Parcel, E-Commerce, Industrial goods, Auto Components, Agri Bags | ||

| Optional Fitments | Rear parking camera and camera inside container; Door opening sensor; Small U hook; Temporary partition; Load sensor with GPS Tracking; Anti fuel theft system; OTP enabled padlock | ||

WATER TANKER ON SIGNA 2818/2821.T BS6

| MODEL | 15KL Water Tanker on SIGNA 2818/2821_48WB |

| Body Dimension | 6100 mm x 2235 mm x 1420 mm |

| Outer Shell Thickness | 3 mm Mild Steel |

| Dish End Thickness | 3 mm Mild Steel |

| Compartment | 4 Compartments |

| Manhole | 4 Manholes |

| Optional Fitment | Pump - MK 20 HSPP |

| Application | Bulk Water Transportation |

REEFER CONTAINER ON LPT 3518/3521_68WB_Cowl BS6

| MODEL | 32 ft MS Reefer Container on LPT 3521 _68WB |

| Body Dimensions (LxWxH) | 9760 mm x 2600 mm x 2800 mm |

| Internal Body Dimensions (LxWxH) | 9410 mm x 2400 mm x 2450 mm |

| Floor | 125 mm Sandwich panel construction with GRP Sheet + PU Foams + Aluminum T Grating |

| Side panel | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) |

| Door | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) |

| Headboard/Front panel | 1.6mm corrugated MS panels + 100mm PU foams + 0.5mm SS Sheet (Food grade) |

| Roof | 125mm PU Foam |

| Ambient Temperature | 50 ⁰C |

| Operating Temperature range | (-20⁰C+25⁰C) |

| Insulation Density | 38-40 kg/m |

| Refrigeration Unit: Make & Model | (Carrier) Supra 1150 / (Thermoking) T1000 |

| Internal Lights | 3 nos. - 6 " LED light sunken type, 24 V, equi-spaced, flush with roof |

| Electricals | As per regulations |

| Standard Accessories | Mudguard flap / side indicators / internal lights / others |

| Painting & Rust Prevention | Polyurethane (PU) finish paint |

| Additional Fitments | Strip curtain with SS brackets |

| Application | Fruits & Vegetables, Dairy, Pharmaceuticals, Meat, Frozen food, Sea food, Beverages & Flowers |

| Optional Fitments | Rear parking camera and camera inside container; Door opening sensor; Small U hook; Temporary partition; Load sensor with GPS tracking; Anti fuel theft system - OTP enabled padlock |

BULKER ON SIGNA 3518/3521.T BS6

| MODEL | 23 CuM Bulker on SIGNA 3518/3521.T_ 52WB | 29 CuM Bulker on SIGNA 3518/3521.T_ 52WB |

| Tank Material | IS 2062 & BSK 46 | IS 2062 & BSK 46 |

| Manholes | 2 x 450 mm manholes for gravity fill | 3 x 450 mm manholes for gravity fill |

| Operating Parameters | Test pressure: 2.86 bar (with certificate); Operating pressure: 2 bar; Air feed: approx. 1 200 cum/hr | Test pressure: 2.86 bar (with certificate); Operating pressure: 2 bar; Air feed: approx. 1 200 cum/hr |

| Loading System | Through manholes | Through manholes |

| Unloading System | By means of pneumatic pressurised dry air with the help of aeration pads | By means of pneumatic pressurised dry air with the help of aeration pads |

| Ladder Arrangement | One ladder with catwalk | One ladder with catwalk |

| Discharge | PN 10 rating wafer type butterfly valveDN 125 for material outlet & DN 80 for air inlet | PN 10 rating wafer type butterfly valveDN 125 for material outlet & DN 80 for air inlet |

| Special Features | Each tank is fitted with aeration and conveyance device | Each tank is fitted with aeration and conveyance device |

| Painting | Shot blast, one coat of epoxy primer and final top coat with one colour, as per requirement | Shot blast, one coat of epoxy primer and final top coat with one colour, as per requirement |

| Accessories | Mudguards, one side catwalk with handrail and spray suppression system, retro reflective markings, SUPD & RUPD as per regulation | Mudguards, one side catwalk with handrail and spray suppression system, retro reflective markings, SUPD & RUPD as per regulation |

| Application | Cement & Fly ash | |

LOAD BODY ON LPT / SIGNA 4225 BS6

| MODEL | 28 ft Fixed Side Deck on LPT / SIGNA 4225 68(P)and62(Tag)WB | 28 ft High Side Deck on LPT / SIGNA 4225 68(P)and62(Tag)WB |

| Body Dimensions (LxWxH) | 8600 mm x 2475 mm x 1386 mm | 8600 mm x 2475 mm x 1830 mm |

| Body Dimensions Internal (LxWxH) | 8465 mm x 2315 mm x 1070 mm | 8465 mm x 2315 mm x 1530 mm |

| Side Panel / Door / Front Panel | Plain Mild Steel 3mm thick | |

| Floor | Plain Mild Steel 4 mm thick | |

| Reflective Tape | On sides & rear | |

| Side Marker | 4 on each side (total 8) | |

| Side Window | 760 mm x 460 mm (both sides) | 1000 mm x 460 mm (both sides) |

| Storage Box | 700 mm x 700 mm x 700 mm | |

| Painting Process | Polyurethane finish paint | |

| Application | Industrial goods, Agri Bags, Steel parts, Pipes, Tubes and Bars, Auto Components, Barrels, Cement Bags, Coal etc | |

| Application | Industrial goods, Agri Bags, Steel parts, Pipes, Tubes and Bars, Auto Components, Barrels, Cement Bags, Coal etc | |

BULKER ON LPT / SIGNA 4225.T BS6

| MODEL | 28 CuM Bulker on LPT 4225 / SIGNA 68(P)and62(Tag)WB | 30 CuM Bulker on LPT 4225 68(P)and62(Tag)WB |

| Tank Material | IS 2062 & BSK 46 | IS 2062 & BSK 46 |

| Manholes | 2 x 450 mm manholes for gravity fill | 2 x 450 mm manholes for gravity fill |

| Operating Parameters | Test pressure: 2.86 bar (with certificate); Operating pressure: 2 bar; Air feed: approx. 1 200 cum/hr | Test pressure: 2.86 bar (with certificate); Operating pressure: 2 bar; Air feed: approx. 1 200 cum/hr |

| Loading System | Through manholes | Through manholes |

| Unloading System | By means of pneumatic pressurised dry air with the help of aeration pads | By means of pneumatic pressurised dry air with the help of aeration pads |

| Ladder Arrangement | One ladder with catwalk | One ladder with catwalk |

| Discharge | PN 10 rating wafer type butterfly valveDN 125 for material outlet & DN 80 for air inlet | PN 10 rating wafer type butterfly valveDN 125 for material outlet & DN 80 for air inlet |

| Special Features | Each tank is fitted with aeration and conveyance device | Each tank is fitted with aeration and conveyance device |

| Painting | Shot blast, one coat of epoxy primer and final top coat with one colour, as per requirement | Shot blast, one coat of epoxy primer and final top coat with one colour, as per requirement |

| Accessories | Mudguards, one side catwalk with handrail and spray suppression system, retro reflective markings, SUPD & RUPD as per regulation | Mudguards, one side catwalk with handrail and spray suppression system, retro reflective markings, SUPD & RUPD as per regulation |

| Application | Cement & Fly ash | |

BULKER ON LPT / SIGNA 4825.T BS6_LDL

| MODEL | 34 CuM Bulker on LPT / SIGNA 4825 LDL | 37 CuM Bulker on LPT / SIGNA 4825 LDL |

| Tank Material | IS 2062 & BSK 46 | IS 2062 & BSK 46 |

| Manholes | 2 x 450 mm manholes for gravity fill | 2 x 450 mm manholes for gravity fill |

| Operating Parameters | Test pressure: 2.86 bar (with certificate); Operating pressure: 2 bar; Air feed: approx. 1 200 cum/hr | Test pressure: 2.86 bar (with certificate); Operating pressure: 2 bar; Air feed: approx. 1 200 cum/hr |

| Loading System | Through manholes | Through manholes |

| Unloading System | By means of pneumatic pressurised dry air with the help of aeration pads | By means of pneumatic pressurised dry air with the help of aeration pads |

| Ladder Arrangement | One ladder with catwalk | One ladder with catwalk |

| Discharge | PN 10 rating wafer type butterfly valveDN 125 for material outlet & DN 80 for air inlet | PN 10 rating wafer type butterfly valveDN 125 for material outlet & DN 80 for air inlet |

| Special Features | Each tank is fitted with aeration and conveyance device | Each tank is fitted with aeration and conveyance device |

| Painting | Shot blast, one coat of epoxy primer and final top coat with one colour, as per requirement | Shot blast, one coat of epoxy primer and final top coat with one colour, as per requirement |

| Accessories | Mudguards, one side catwalk with handrail and spray suppression system, retro reflective markings, SUPD & RUPD as per regulation | Mudguards, one side catwalk with handrail and spray suppression system, retro reflective markings, SUPD & RUPD as per regulation |

| Application | Cement & Fly ash | |