In this ever challenging business environment as we thrive to tailor make our offerings to your exact requirements, we have taken a step further to provide you with the TML Fully Built Solutions.

Today's fiercely competitive business scenario means that you need to be ready on Day one with your asset and need to focus on your business fully. That is where we step in to take away all your worries.

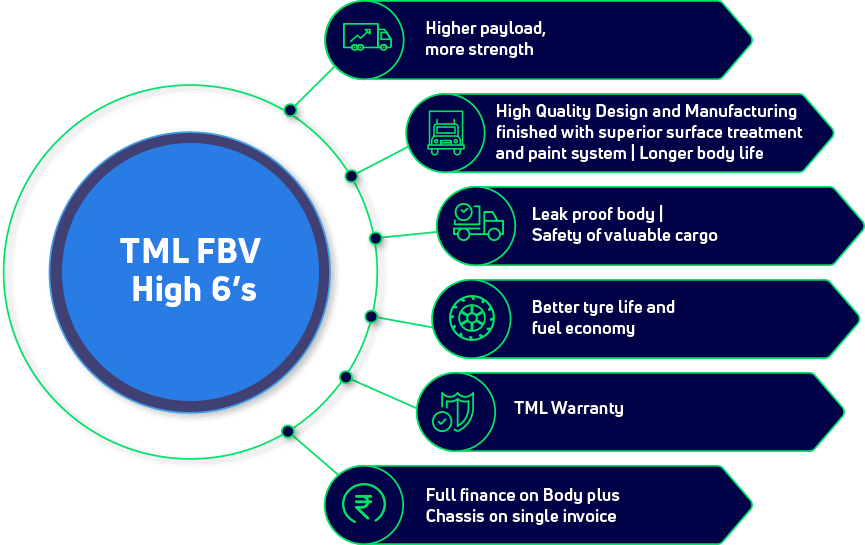

The Fully Built Solutions' range from Tata Motors promises the High 6s that ensure you earn the maximum commercial gains and have complete peace of mind when it comes to your application requirements including the operation and maintenance of the bodies.

Now choose from the wide range of solutions on our truck and tractor platforms and enjoy the convenience of Ready-to-run vehicles, single invoice funding, hassle free registration, durable and reliable bodies designed, manufactured and maintained with the best in class processes, materials and techniques ensuring you earn more per trip.

Excellence and Trust are what we serve with our Fully Built Solutions range now with the Tata Motors High 6s

Take your business to newer heights with our world class chassis with optimally designed bodies that offer higher and faster return on investment giving you complete peace of mind.

TRACTOR TRAILERS

SKELETAL 2 AXLE TRAILER ON 4018.S BS6

| MODEL | 7 000 mm (7 m) 2A 12TL Skeletal Trailer | 12 000 mm (12 m) 2A 12TL Skeletal Trailer |

| Body Dimensions (LxWxH) | 7 163 mm x 2 590 mm | 12 200 mm x 2 590 mm |

| Chassis | All steel welded construction. 2 nos. main longitudinal members are of high strength lighter weight parallel flange beam running along full length of the trailer. Cross members - rolled or folded of material IS-2062 / equivalent - are positioned at suitable locations. 12 nos. of twist lock shall be provided to suit 1 no.-40 feet or 2 nos.–20 feet or 1 no.-20 feet ISO container at middle. | |

| Landing Leg | Two-speed landing leg shall be provided at the front end. Make: York 25A / equivalent | |

| Axles | 2 nos. 12T heavy duty axles shall be provided. Make TATA/ York / equivalent | |

| King Pin | 2" king pin equivalent to IS: 6763 Part I provided | |

| Suspension | 9 leaves heavy duty tandem axle multi leaf spring suspension with load equalizing brackets to be provided. Make: YORK / equivalent | |

| Tyre & Wheel Rim | 10 x 20 / 10R X 20 - 16 PR – 08 nos.; 7.5.0 x 20 - 08 nos. | |

| Brakes | Twin line air brake system coupled to tractor brake system. Trailer brakes are actuated from tractor. T 24 / T 30 brake chamber/ Spring brake actuator shall be provided on all axles. Parking brake shall be manually actuated |

|

| Electricals | 24 V DC electricals include tail lamp, brake lamp and direction indicator lamps fitted at rear end of trailer. Side marker lamps shall be provided on both sides | |

| Surface Preparation | Trailer surface shall be shot blasted and cleaned | |

| Painting | One coat of primer and one coat of finish paint with colour of customer's choice | |

| Other Fitments | Fitments of SUPD, RUPD, reflectors on both sides and rear shall be provided as per CMVR | |

| Application | Transportation of Shipping Containers | |

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

FLAT BED 2 AXLE TRAILER ON 4018.S BS6

| MODEL | 7 000 mm (7 m) 2A 12TL Flatbed Trailer | 12 000 mm (12 m) 2A 12TL Flatbed Trailer |

| Body Dimensions (LxWxH) | 7 163 mm x 2 590 mm (23 ft 7 inch x 8 ft 6 inch) | 12 200 mm x 2 590 mm (40 ft 1 inch x 8 ft 6 inch) |

| Chassis | All steel welded construction. Main longitudinal members: 2 nos. “I” section of material IS:2062 / equivalent running along full length of the trailer. Rolled cross member of material IS-2062 / equivalent are positioned at suitable locations. 12 nos. of twist lock shall be provided to suit 1 no.- 40 feet or 2 nos.–20 feet or 1 no.-20 feet ISO container at middle. Floor shall be of 3.15 mm thick chequered sheet | |

| Landing Leg | Two-speed landing leg shall be provided at the front end. Make: York 25A / equivalent | |

| Axles | 2 nos. 12T heavy duty axles shall be provided. Make TATA / York or equivalent | |

| King Pin | 2" king pin equivalent to IS: 6763 Part I provided | |

| Suspension | 9 leaves heavy duty tandem axle multi leaf spring suspension with load equalizing brackets to be provided. Make: YORK / equivalent | |

| Tyre & Wheel Rim | 10 x 20 / 10R x 20 - 16 PR – 08 nos.; 7.5.0 x 20 - 08 nos. | |

| Brakes | Twin line air brake system coupled to tractor brake system. Trailer brakes are actuated from tractor. T 24 / T 30 brake chamber / spring brake actuator shall be provided on all axles. Parking brake shall be manually actuated |

|

| Electricals | 24 V DC electricals include tail lamp, brake lamp and direction indicator lamps fitted at rear end of trailer. Side marker lamps shall be provided on both sides | |

| Surface Preparation | Trailer surface shall be shot blasted and cleaned | |

| Painting | One coat of primer and one coat of finish paint with colour of customer's choice | |

| Other Fitments | Fitments of SUPD, RUPD, reflectors on both sides and rear shall be provided as per CMVR | |

| Application | Steel Coils, Shipping Containers, Marble Blocks, Agri Bags, Jumbo Bags, Cement Bags etc. | |

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

SKELETAL 3 AXLE TRAILER ON 4625.S BS6

| MODEL | 7 000 mm (7 m) 3A 12TL Skeletal Trailer | 12 000 mm (12 m) 3A 12TL Skeletal Trailer |

| Body Dimensions (LxWxH) | 7 163 mm x 2 590 mm | 12 200 mm x 2 590 mm |

| Chassis | All steel welded construction. 2 nos. main longitudinal members are of high strength lighter weight Parallel flange beam running along full length of the trailer. Cross members - rolled or folded of material IS-2062 / equivalent - are positioned at suitable locations. 12 nos. of twist lock shall be provided to suit 1 no.-40 feet or 2 nos.–20 feet or 1 no.-20 feet ISO container at middle. | |

| Landing Leg | Two-speed landing leg shall be provided at the front end. Make: York 25A / equivalent | |

| Axles | 3 nos. 12T heavy duty axles shall be provided. Make TATA / York / equivalent | |

| Axles | 3 nos. 12T heavy duty axles shall be provided. Make TATA / York / equivalent | |

| King Pin | 2" king pin equivalent to IS: 6763 Part I provided | |

| Suspension | 10 leaves heavy duty tridem axle multi leaf spring suspension with load equalizing brackets to be provided. Make: YORK / equivalent | |

| Tyre & Wheel Rim | 10 x 20 / 10R x 20 - 16 PR - 12 nos.; 7.5.0 x 20 - 12 nos. | |

| Brakes | Twin line air brake system coupled to tractor brake system. Trailer brakes are actuated from tractor. T 24 / T 30 brake chamber / spring brake actuator shall be provided on all axles. Parking brake shall be manually actuated |

|

| Electricals | 24 V DC electricals include tail lamp, brake lamp and direction indicator lamps fitted at rear end of trailer. Side marker lamps shall be provided on both sides | |

| Surface Preparation | Trailer surface shall be shot blasted and cleaned | |

| Painting | One coat of primer and one coat of finish paint with colour of customer's choice | |

| Other Fitments | Fitments of SUPD, RUPD, reflectors on both sides and rear shall be provided as per CMVR | |

| Application | Transportation of Shipping Containers | |

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

FLATBED 3 AXLE TRAILER ON 4625.S BS6

| MODEL | 7 000 mm (7 m) 3A 12TL Flatbed Trailer | 12 000 mm (12 m) 3A 12TL Flatbed Trailer |

| Body Dimensions (LxWxH) | 7 163 mm x 2 590 mm | 12 200 mm x 2 590 mm |

| Chassis | All steel welded construction. Main longitudinal members: 2 nos. “I” section of material IS:2062 / equivalent running along full length of the trailer. Rolled cross member of material IS-2062 / equivalent are positioned at suitable locations. 12 nos. of twist lock shall be provided to suit 1 no.- 40 feet or 2 nos.–20 feet or 1 no.-20 feet ISO container at middle. Floor shall be of 3.15 mm thick chequered sheet | |

| Landing Leg | Two-speed landing leg shall be provided at the front end. Make: York 25A / equivalent | |

| Axles | 3 nos. 12T heavy duty axles shall be provided. Make TATA / York / equivalent | |

| King Pin | 2" king pin equivalent to IS: 6763 Part I provided | |

| Suspension | 10 leaves heavy duty tridem axle multi leaf spring suspension with load equalizing brackets to be provided. Make: YORK / equivalent | |

| Tyre & Wheel Rim | 10 x 20 / 10R x 20 - 16 PR - 12 nos.; 7.5.0 x 20 - 12 nos. | |

| Brakes | Twin line air brake system coupled to tractor brake system. Trailer brakes are actuated from tractor. T 24 / T30 brake chamber / spring brake actuator shall be provided on all axles. Parking brake shall be manually actuated |

|

| Electricals | 24 V DC electricals include tail lamp, brake lamp and direction indicator lamps fitted at rear end of trailer. Side marker lamps shall be provided on both sides | |

| Surface Preparation | Trailer surface shall be shot blasted and cleaned | |

| Painting | One coat of primer and one coat of finish paint with colour of customer's choice | |

| Other Fitments | Fitments of SUPD, RUPD, reflectors on both sides and rear shall be provided as per CMVR | |

| Application | Steel Coils, Shipping Containers, Marble Blocks, Agri Bags, Jumbo Bags, Cement Bags etc. | |

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

SIDEWALL 3 AXLE TRAILER ON 4625.S BS6

| MODEL | 9 000 mm (9 m)/30 ft (3 ft) Sidewall Trailer | 9 000 mm (9 m)/30 ft (4 ft) Sidewall Trailer | 10 000 mm (10 m)/32 ft (4 ft) Sidewall Trailer | 10 000 mm (10 m)/32 ft (5 ft) Sidewall Trailer | 10 000 mm (10 m)/32 ft (4 ft 2LA_3PS) Sidewall Trailer |

| Body Dimensions (LxWxH) | 9 150 mm x 2 590 mm x 914 mm | 9 150 mm x 2 590 mm x 1 219 mm | 9 800 mm x 2 590 mm x 1 219 mm | 9 800 mm x 2 590 mm x 1 524 mm | 9 800 mm x 2 590 mm x 1 219 mm |

| Chassis | All steel welded construction. Main longitudinal members: 2 nos. “I” section of material IS:2062 / equivalent running along full length of the trailer. Rolled cross member of material IS-2062 / equivalent are positioned at suitable locations. Floor shall be of 4 mm thick plain sheet | ||||

| Landing Leg | One set of two-speed landing leg shall be provided at the front end. Make: YORK (YTE 25A) / equivalent | ||||

| Axles | 3 nos. 12T heavy duty axles are provided. Make: YORK / equivalent | ||||

| King Pin | 2” king pin - weldon equivalent to IS: 6763 Part I provided. Make: YORK / equivalent | ||||

| Suspension | 10 leaves Tridem heavy duty suspension. Make: YORK YTE 75 / equivalent | ||||

| Tyre & Wheel Rim | 10.00 x 20 – 16 PR – 12 nos. ; 7.50 x 20 – 12 nos. | ||||

| Brakes | Twin line air brake system coupled to tractor brake system. Trailer brakes are actuated from tractor. T24 / T 30 brake chamber shall be provided on all axles. Parking brake shall be manually actuated | ||||

| Electricals | 24 V DC electricals include tail lamp, brake lamp and direction indicator fitted on rear end of trailer. Red reflectors are also provided. Side marker lamps are provided at each side of the trailer | ||||

| Surface Preparation | Trailer surface shall be shot blasted and cleaned | ||||

| Painting | 2 coat primer and one coat quick dry paint as finish paint with colour of customer's choice | ||||

| Other Fitments | Fitments of SUPD, RUPD, reflectors on both sides and rear shall be provided as per CMVR | ||||

| Application | Cement Bags, Steel Pipes, tubes & bars, Agri Bags, Jumbo bags, Tiles, Pet coke et | ||||

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

TIP TRAILER 3 AXLE ON 4625.S BS6

| Model [Volumetric Capacity (CuM)] | 24 CuM Tip Trailer | 26 CuM Tip Trailer | 30 CuM Tip Trailer |

| Inside (LxWxH) | 6 882 mm x 2 400 mm x 1 450 mm | 6 902 mm x 2 400 mm x 1 560 mm | 7 788 mm x 2 400 mm x 1 600 mm |

| Steel | YS (MPA) - 450-500 min, UTS (MPA) - 500-640 / equivalent | ||

| Steel Thickness - Flr x SB x HB x TD | 4 mm x 3 mm x 3 mm x 3 mm (BSK-46) / equivalent | ||

| Tipping Kit | FE-149 (HYVA) / equivalent | FE-169 (HYVA) / equivalent | |

| Axle | 3 nos. 12T heavy duty axles with manual slack adjuster are provided. Make: TATA / YORK / equivalent | ||

| Suspension Type | Tridem; MAKE - YTE 75/90 / equivalent | ||

| King Pin Size | 2" bolt-in type as per AS 2175-1995. | ||

| Landing Leg Type | Twin-speed telescopic; Make - ARAI Approved, Capacity - 28T | ||

| Tyre & Wheel Rim | 10 x 20 /10R x 20 - 16 PR - 12 nos.; 7.50 x 20 - 12 nos. | ||

| Brake Type | Air operated T 24 / T 30 brake chamber / spring brake actuator | ||

| Painting | 1 - PU paint with colour of customer's choice; 2 - Inner body to be pretreated before paint; 3 - Anti-rust agent before paint at water accumulation area | ||

| Shot Blasting & Primer Coating | All child parts, chassis and body to be shot blasted & primed before top coat assembly | ||

| Electricals | Side marker lamp - 5 nos each side; Top marker lamp - 2 nos; Tail lamp - 2 nos | ||

| Stabilizer | Fabricated (To be mounted on floor plate with 6 mm thick plate) | ||

| Chassis | Rolled Beam / equivalent | ||

| Application | Pet Coke, Coal, Construction aggregates | ||

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

FLATBED 3 AXLE TRAILER ON 5530.S Bell Crank / Bogie BS6

| MODEL | 12 000 mm (12 m) 3A 12TL Flatbed Trailer |

| Body Dimensions (LxWxH) | 12 200 mm x 2 590 mm |

| Chassis | All steel welded construction. Main longitudinal members: 2 nos. “I” section of material IS:2062 / equivalent running along full length of the trailer. Rolled cross member of material IS-2062 / equivalent are positioned at suitable locations. 12 nos. of twist lock shall be provided to suit 1 no.- 40 feet or 2 nos.–20 feet or 1 no.-20 feet ISO container at middle. Floor shall be of 3.15 mm thick chequered sheet |

| Landing Leg | One set of two-speed landing leg shall be provided at the front end. Make: YORK (YTE 25A) / equivalent |

| Axles | 3 nos. 13T heavy duty axles are provided. Make: TATA / YORK / equivalent |

| King Pin | 2” king pin - weldon equivalent to IS: 6763 Part I provided. |

| Suspension | 10 leaves Tridem heavy duty suspension. Make: YORK YTE 75 / equivalent |

| Tyre & Wheel Rim | 10 x 20 / 10R x 20- 16 PR - 12 nos.; 7.50 x 20 - 12 nos. |

| Brakes | Twin line air brake system coupled to tractor brake system. Trailer brakes are actuated from tractor. T 24 / T 30 brake chamber / spring brake actuator shall be provided on all axles. Parking brake shall be manually actuated |

| Electricals | 24 V DC electricals include tail lamp, brake lamp and direction indicator fitted on rear end of trailer. Red reflectors are also provided. Side marker lamps are provided at each side of the trailer |

| Surface Preparation | Trailer surface shall be shot blasted and cleaned. |

| Painting | Surface cleaned by shot blasting, 2 coat primer and one coat quick dry paint as finish paint with colour of customer's choice |

| Other Fitments | Fitments of SUPD, RUPD, reflectors on both sides and rear shall be provided as per CMVR |

| Application | Steel Coils, Shipping Containers, Marble Blocks, Agri Bags, Jumbo Bags, Cement Bags etc. |

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

SEMI LOW BED 3 AXLE TRAILER ON 5530.S Bell Crank/ Bogie BS6

| MODEL | 12 200 mm (12.2 m) Semi Lowbed Trailer | 12 500 mm (12.5 m) Semi Lowbed Trailer |

| Body Dimensions (LxWxH) | 12 200 mm x 2 590 mm | 12 500 mm x 2 590 mm |

| Chassis | All steel welded construction. Main longitudinal members: 2 nos. “I” section of material IS:2062 / equivalent running along full length of the trailer. Rolled cross member of material IS-2062 / equivalent are positioned at suitable locations. Floor shall be of 3.15 mm thick chequered sheet | |

| Landing Leg | One set of two-speed landing leg shall be provided at the front end. Make: YORK (YTE 25A) / equivalent | |

| Axles | 3 nos. 13T heavy duty axles are provided. Make: TATA / YORK / equivalent | |

| King Pin | 2” king pin - weldon equivalent to IS: 6763 Part I provided. | |

| Suspension | 10 leaves Tridem heavy duty suspension. Make: YORK YTE 75 / equivalent | |

| Tyre & Wheel Rim | 10 x 20 / 10R x 20 - 16 PR - 12 nos.; 7.50 x 20 - 12 nos. | |

| Brakes | Twin line air brake system coupled to tractor brake system. Trailer brakes are actuated from tractor. T 24 / T 30 brake chamber / spring brake actuator shall be provided on all axles. Parking brake shall be manually actuated | |

| Electricals | 24 V DC electricals include tail lamp, brake lamp and direction indicator fitted on rear end of trailer. Red reflectors are also provided. Side marker lamps are provided at each side of the trailer | |

| Surface Preparation | Trailer surface shall be shot blasted and cleaned | |

| Painting | Surface cleaned by shot blasting, 2 coat primer and one coat quick dry paint as finish paint with colour of customer's choice | |

| Other Fitments | Fitments of SUPD, RUPD, reflectors on both sides and rear shall be provided as per CMVR | |

| Application | Transportation of Machines Like Excavators, Steel Coils, Marble Blocks, Agri Bags, Jumbo Bags, Cement Bags etc. | |

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

SIDE WALL 3 AXLE TRAILER ON 5530.S Bell Crank/ Bogie BS6

| MODEL | 10 000 mm (10 m)/32 ft (3 ft) Sidewall Trailer | 10 000 mm (10 m)/32 ft (4 ft) Sidewall Trailer | 10 400 mm (10.4 m)/34 ft (4 ft) Sidewall Trailer | 10 400 mm (10.4 m)/34 ft (5 ft) Sidewall Trailer | 10 400 mm (10.4 m) 10.4 m/34 ft (6 ft plain sheet) Sidewall Trailer |

| Body Dimensions (LxWxH) | 9 800 mm x 2 590 mm x 914 mm | 9 800 mm x 2 590 mm x 1 219 mm | 10 400 mm x 2 590 mm x 1 219 mm | 10 400 mm x 2 590 mm x 1 524 mm | 10 400 mm x 2 590 mm x 1 829 mm |

| Chassis | All steel welded construction. Main longitudinal members: 2 nos. “I” section of material IS:2062 / equivalent running along full length of the trailer. Rolled cross member of material IS-2062 / equivalent are positioned at suitable locations. Floor shall be of 4 mm thick plain sheet | ||||

| Landing Leg | One set of two-speed landing leg shall be provided at the front end. Make: YORK (YTE 25A) / equivalent | ||||

| Axles | 3 nos. 13T heavy duty axles are provided. Make: TATA / YORK / equivalent | ||||

| King Pin | 2” king pin - weldon equivalent to IS: 6763 Part I provided. | ||||

| Suspension | 11 leaves Tridem heavy duty suspension. Make: YORK YTE 75 / equivalent | ||||

| Tyre & Wheel Rim | 10 x 20 / 10R x 20 - 16 PR - 12 nos.; 7.50 x 20 - 12 nos. | ||||

| Brakes | Twin line air brake system coupled to tractor brake system. Trailer brakes are actuated from tractor. T24 / T 30 brake chamber / spring brake actuator shall be provided on all axles. Parking brake shall be manually actuated | ||||

| Electricals | 24 V DC electricals include tail lamp, brake lamp and direction indicator fitted on rear end of trailer. Red reflectors are also provided. Side marker lamps are provided at each side of the trailer | ||||

| Surface Preparation | Trailer surface shall be shot blasted and cleaned | ||||

| Painting | Surface cleaned by shot blasting, 2 coat primer and one coat quick dry paint as finish paint with colour of customer's choice | ||||

| Other Fitments | Fitments of SUPD, RUPD, reflectors on both sides and rear shall be provided as per CMVR | ||||

| Application | Cement Bags, Steel Pipes, tubes & bars, Agri Bags, Jumbo bags, Tiles, Pet coke etc. | ||||

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

TIP TRAILER 3 AXLE ON 5530.S Bell Crank / Bogie BS6

| Model [Volumetric Capacity (CuM)] | 24 CuM Tip Trailer | 26 CuM Tip Trailer | 32 CuM Tip Trailer | 36 CuM Tip Trailer |

| Inside (LxWxH) | 7 732 mm x 2 400 mm x 1 290 mm | 7 750 mm x 2 400 mm x 1 400 mm | 7 811 mm x 2 400 mm x 1 700 mm | 9 139 mm x 2 400 mm x 1 640 mm |

| Steel | YS (MPA) - 450-500 min, UTS (MPA) - 500-640 / equivalent | |||

| Steel Thickness - Flr x SB x HB x TD | 5 mm x 3 mm x 3 mm x 3 mm (BSK-46) / equivalent | 5 mm x 3 mm x 3 mm x 3 mm (BSK-46) / equivalent | 4 mm x 3 mm x 3 mm x 3 mm (BSK-46) / equivalent | 5 mm x 3 mm x 3 mm x 3 mm (BSK-46) / equivalent |

| Tipping Kit | FE-169 (HYVA) / equivalent | FE-169 (HYVA) / equivalent | FE-169 (HYVA) / equivalent | FE-191 (HYVA) / equivalent |

| Axle | 3 nos. 12T heavy duty axles with manual slack adjuster are provided. Make: TATA / YORK / equivalent | |||

| Suspension Type | Tridem; Make - YTE 75/90 / equivalent | |||

| King Pin Size | 2" bolt-in type as per AS 2175-1995. | |||

| Landing Leg Type | Twin-speed telescopic; Make - ARAI approved; Capacity - 28T | |||

| Tyre & Wheel Rim | 10 x 20 / 10R x 20- 16 PR - 12 nos.; 7.50 x 20 - 12 nos. | |||

| Brake | Air-operated T-24 / T 30 brake chamber / spring brake actuator | |||

| Painting | 1 - PU paint with colour of customer's choice; 2 - Inner body to be pretreated before paint; 3 - Anti-rust agent before paint at water accumulation area | |||

| Shot Blasting & Primer Coating | All child parts, chassis and body to be shot blasted & primed before top coat assembly | |||

| Electricals | Side marker lamp - 5 nos each side; Top marker lamp - 2 nos; Tail lamp - 2 nos | |||

| Stabilizer | Fabricated (To be mounted on floor plate with 6 mm thick plate) | |||

| Chassis | Rolled Beam or equivalent | |||

| Application | Pet Coke, Coal, Construction aggrega | |||

* All trailers are available with Lift Axle(LA) and/or AIS 113 compliant variants

BULKER 3 AXLE TRAILER ON 5530.S BS6

| MODEL | 40 CuM Bulker | 42 CuM Bulker |

| Shell Thickness / Material | 5 mm ST 52 / equivalent | 5 mm & 4 mm (IS2062 & BSK46) / equivalent |

| Dish End | 5 mm ST 52 / equivalent | 5 mm (BSK46) / equivalent |

| Manhole (Loading) Dia | 450 mm | 450 mm |

| Operating Parameters | Test pressure: 2.86 bar (with certificate); Operating pressure: 2 bar; Air feed: approx. 1 200 cum/hr | Operating pressure: 1.85 bar |

| Main Beam | The main chassis is a ladder type construction with cross members | The main chassis is a ladder type construction with cross members |

| Landing Legs | Two-speed landing legs | Two-speed landing legs |

| Axles | TATA / YORK / FUWA / BPW / equivalent | TATA / YORK / FUWA / BPW / equivalent |

| Suspension | Tridem suspension | Tridem suspension |

| Tyres | 10 x 20 / 10R x 20 / 11 x 20 / 11R x 20 - 16 Ply | 10 x 20 / 10R x 20 / 11 x 20 / 11R x 20 - 16 Ply |

| Electricals & Reflective Tapes | As per regulations | As per regulations |

| Painting | Shot blast, one coat of epoxy primer and final top coat with one colour, as per requirement | Shot blast, one coat of epoxy primer and final top coat with one colour, as per requirement |

| Accessories | Mudguards, one side catwalk with handrail and spray suppression system, retro reflective markings, SUPD & RUPD as per regulation | Mudguards, one side catwalk with handrail and spray suppression system, retro reflective markings, SUPD & RUPD as per regulation |

| Application | Cement & Fly ash | |